DLyte | The First Dry Electropolishing Process

- Precision Finishing Inc.

- Feb 4, 2021

- 3 min read

Updated: Apr 17, 2024

A revolutionary Dry Electropolishing Technology

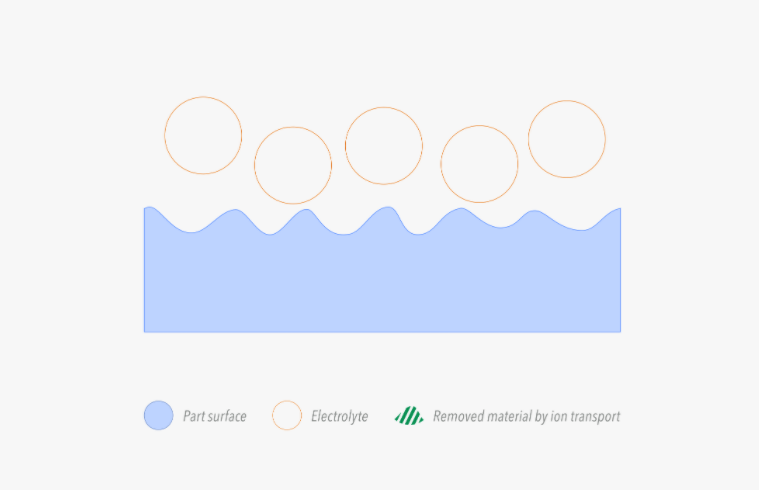

DryLyte® new patented technology for grinding and polishing metals by ion transport using free solid bodies. A revolutionary dry electropolishing that is based in a solid media. DLyte is a polishing system for metal parts that require high performance or superior finishing.

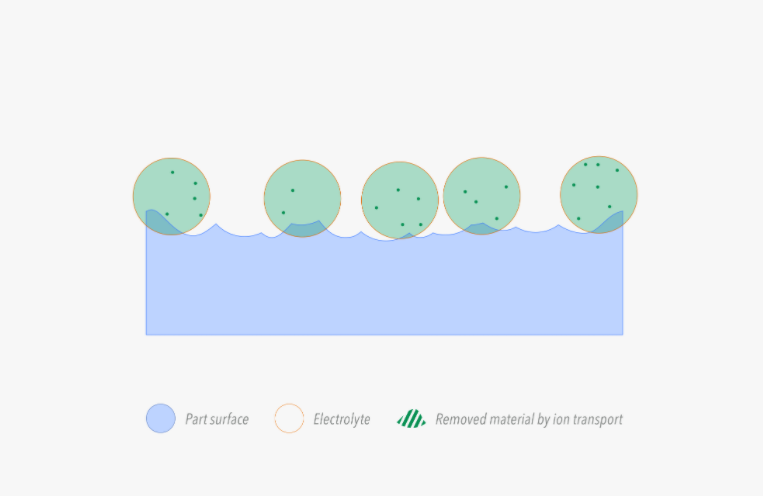

Unlike traditional polishing systems, DLyte system obtains consistent finish avoiding any marks on the surface, patterns such as those generated by machining, and is able to process complex geometries without generating micro scratches on the surface. DLyte respects the tolerances of the piece, delivering a mirror finish.

How it works

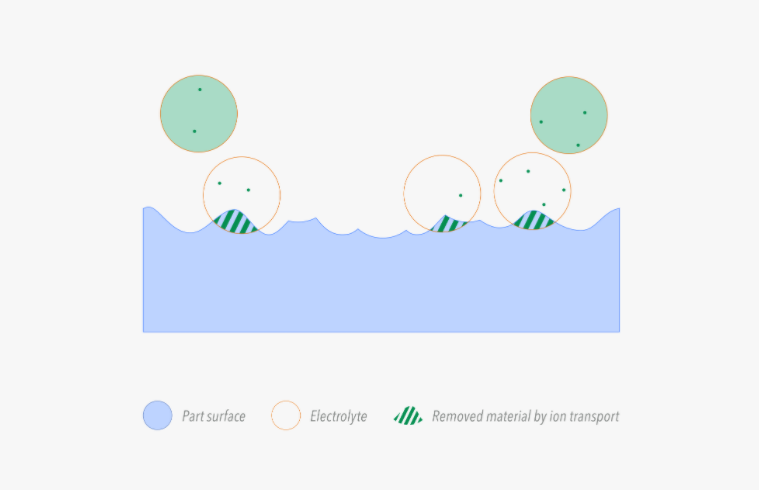

“The process extracts the material only from the peaks of the roughness, it does not round the edges but penetrates the internal cavities of the piece to which annot be accessed mechanically”.

The technology works on the principle of ion transport, utilizing the dry electrolyte to slowly work the asperities of the roughness profile, where after a specified time, the part surface has been plateaued without the use of physical abrasive. This results in highly uniform functional surfaces with brilliant finishes.

The Benefits of the technology

Achieves homogeneous results across the surface and eliminates micro- scratches. The system works efficiently at micro and macroscopic level.

Respects the tolerances and preserves the initial shape, even the cutting edges. It is not rounding the edges as there is no abrasion of the surface.

Ra under 0,05 μm. The improvement of the surface quality from 10 μm to 0,8 μm in rotor blade turbines improves the efficiency, reducing the turbine inlet temperature with the associated turbine durability increase.

Enhances negative surface skewness (rsk) which increases the surface bearing contact area (allowing uniform lubricant film distribution) improving the bearing ratio and reducing the friction between the pieces.

Avoids generating grinding texture patterns, improving wear and fracture resistance, and improving fatigue resistance. Isotropic surfaces.

Process & Production benefits of the technology

Proved Biocompatibility The Medical and Dental Device sectors require clinically proven processes and products which guarantee their compliance with the most demanding safety regulations.

The manufacturer must ensure that the devices meet all appropriate requirements and in particular perform a risk/ benefit analysis and evaluate the biocompatibility and toxicity of the materials used.

The product can be considered non-cytotoxic. The study has been made according to the specifications of standard UNE-EN-ISO 10993-5:2009

DLyte has proven the Biocompatibility of the products processed with DLyte System.

Corrosion resistance

The corrosion resistance of a piece of equipment is dependent not only on the selection of the most suitable alloy but also upon the correct treatment of the material. Many applications require a surface treatment to be performed after polishing to comply with the corrosion resistance requirements.

DLyte is the unique system able to remove roughness and improve the co- rrosion resistance of the metal pieces at the same time reducing the number of processes required in the manufacturing process. DLyte achieves better corrosion resistance than liquid electropolishing.

Easy waste management and Low waste and water consumption

Liquid electropolishing installations require removal of electrolyte sludge regularly and careful handling and adherence to health and safety regulations. Disposal of used liquid electrolyte and sludge is usually handled by specialized services to ensure compliance with environmental regulations. Disposal of used post-dip citric acid may also require hazardous waste disposal, since the metal by-products change the chemical nature of citric acid.

DLyte system does not require closed-up system to recycle water and sludge waste treatment machinery with the corresponding space, labor, water and environmental license costs savings. The disposal of the dry electrolyte is handled by Standard services.

Talk to us about your application! We are here to help!

Our Passion is in the Process

Comments